Product Information

Product Code:BOSIL-OH Polymer

(Hydroxyl-terminated polydimethylsiloxane)

Synonyms:107 Silicone rubber; Hydroxyl silicone oil; RTV 107 Silicone rubber, Dimethyl hydroxyl silicone oil

Molecular formula:OH(CH3)2Si[O(CH3)2Si]nOSi(CH3)2OH

CAS NO.: 63148-60-7

Appearance:Colorless, transparent, free of mechanical impurities.

Properties and Reactivity

BOSIL-OH Polymer not only has similar properties to dimethylsiloxane (such as methyl silicone oil), but also has special properties brought by active silanol terminated polydimethylsiloxane.

Under the action of acid and alkaline medium with organic alkoxy silane, organic acyloxy silane, amino silane, it can occur condensation reaction to form the high-molecular polymer; reacts with borate, titanate, silicate, silicon-hydrogen bond, etc. to form cross-linked combination products.

As the main raw material in RTV silicone rubber, defoaming agent, silicone products;

As rubber roller material in the automobile, machinery industry;

As caulking sealing material in the building industry;

It has very good demoulding performance for two-component silicone rubber and is suitable for manufacturing precision molds and impression materials.

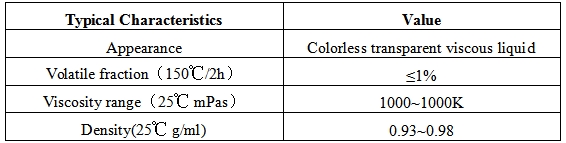

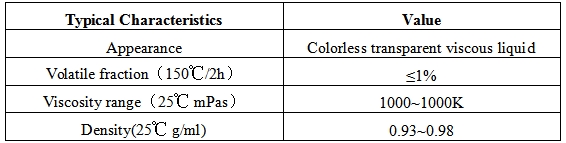

Technical Data

Note: the above data is for reference only, cannot be as a technical specification. Products of various viscosities can be customized.

Application

RTV silicone rubber

BOSIL-OH Polymer is mainly used as the base raw material of RTV silicone rubber, all kinds of silicone rubber products made from it are resistant to high and low temperature, oxidation resistance, water resistance, aging resistance, and has excellent electrical insulation, etc.

Widely used in construction, home decoration, electronics, electrical appliances, national defense high-tech fields and other industrial sectors.

The preparation of block polymers and defoaming agent

Low molecular weight BOSIL-OH Polymer is often used in the preparation of block polymers and defoaming agents.

Widely used in silicone rubber products industry, it is an excellent structure control agent commonly used in silicone rubber processing, which can improve the processing performance of silicone rubber, prolong the storage life of rubber materials, increase the transparency of rubber products, and improve the mechanical properties of silicone rubber.

Also used for the preparation of cationic, anionic, non-ionic hydroxyl silicone oil emulsion (hydroxyemulsion), if used with Hydrogen silicone oil, it is a good treatment agent for fabric, leather, paper.

Softener

After combining hydroxyl silicone oil and dimethylhydrogensiloxane, a silicone emulsion is made, that used for fabric treatment, forming silicone film covering the surface of the fabric, to make the treated fabric soft hard moderate and has the characteristics of waterproof.

BOSIL-OH Polymer forms an elastic film on the fabric surface after baking, which is insoluble in lye and has good washing resistance.

The principle of BOSIL-OH Polymer used in fabric treatment: The fabric is made of interwoven warp and weft yarns, and the yarns are composed of short fibers twisted or long filaments combined. Therefore, the surface friction properties between fibers or yarns will affect their relative movement. After silicone oil treatment, the friction coefficient of fibers and yarns is reduced, and the resistance to movement between interweaving points is reduced. The fabric is easily deformed in the direction of hand force, showing softness and smoothness. When the needle pierces the yarn, the yarn gets out of the way and is not easily broken, so its sewing performance is greatly improved. In addition, the reduction of friction coefficient also leads to the reduction of frictional electrification, and the anti-static performance can also be improved. The elastic film formed by silicone oil can also improve the elasticity of fabrics and improve the deformation recovery of fibers and yarns.

As raw materials of special silicone oil

Amino silicone oil can be synthesized by reaction of BOSIL-OH Polymer and amino silane.

For example, both LT-602 (N-(β-AMINO ETHYL) -γ-AMINO PROPYL METHYL DIMETHOXY SILANE) and BOSIL-OH Polymer can be polymerized under alkaline conditions.

Predict the average molecular weight of the product by measuring the viscosity of the sample. The activation energy of the reaction is low. If the reaction is carried out under moderate conditions with a temperature >80℃, the reaction products methanol and water need to be discharged from the system under vacuum conditions. When the reaction is carried out under normal pressure, the reaction time needs to be extended and the reaction temperature must be increased to around 105℃. If the water in the reaction is not well discharged, it will lead to high viscosity and turbidity of the product, but does not affect the performance. End-capping agent can be added to control the viscosity of the product during polymerization, such as BOSIL-107(HEXAMETHYLDISILOXANE), but this will cause the product to lose the hydroxyl groups and reduce cross-linking film formation.

BOSIL-OH Polymer can react with polyurethane to produce polysiloxane polyurethanes. Before the reaction, the hydroxyl silicone oil must be pretreated to remove water and reduce the occurrence of side reactions. The actual reaction conditions can be to mix the polyisocyanate curing agent and dibutyltin dilaurate catalyst first, then pass through nitrogen protection, and add dropwise hydroxy silicone oil to react under the condition of keeping the temperature at 70°C. During the reaction, the reaction progress is determined by detecting the content of -NCO groups. When its content is less than half of the added amount, cool down and discharge the material and store it away from light.

Hydroxy silicone oil and triethanolamine generate amino-modified silicone oil under the action of a catalyst. This reaction is a polycondensation reaction between polymers, which is easier to carry out and can occur at a lower temperature. The catalyst for the reaction uses an acid with good dehydration ability, where the catalytic effect is phosphoric acid > sulfuric acid > hydrochloric acid. The solvent for the reaction is benzene. At this time, the temperature needs to be higher than the boiling point of the solvent to facilitate separation. At the same time, it cannot be too high, otherwise the reaction system will easily oxidize and become darker.

鄂公网安备 42900402000406号

鄂公网安备 42900402000406号 Home

Home Tel

Tel Product

Product