Product Information

Chemical Name:VINYLTRIMETHOXYSILANE

Product Code:LT-171

Molecular Formula:C5H12O3Si

Molecular Weight:148.2

CAS NO.:2768-02-7

Properties and Reactivity

LT-171 is a bifunctional organosilane with a vinyl functional group and a hydrolysable inorganic triethoxysilyl group. This bifunctional structure gives LT-171 special properties: it is able to bond inorganic materials (e.g., glass, metal, fillers, etc.) to organic polymers (e.g., thermosets, thermoplastics, elastomers) organically, thus acting as an adhesion promoter and/or surface modifier.

It is a colorless transparent liquid, low viscosity with a typical aromatic odour.

LT-171 hydrolyses its methoxyl groups in the presence of water vapour to produce methanol and reactive silanol groups that can form bonds with various inorganic substrates or from these groups to each other to form silicon-oxygen bonds. In the presence of a suitable peroxide initiator, the vinyl end of its upper part, which is organic in nature, will also react with suitable polymers.

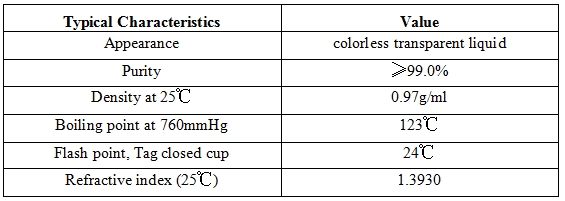

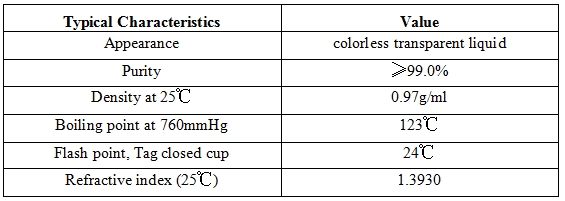

Technical Data

Note: the above data is for reference only, cannot be as a technical specification.

Application

Moisture curing of polymers

LT-171 is suitable for wet-curing polymers such as polyethylene, a process characterised by the grafting of vinyl silane to the polymer material during extrusion by peroxide initiation. After the grafting reaction the polymer can still be thermoplastically treated. It is only through water vapour treatment (water bath at 80-100°C, vapour bath or even under ambient conditions) that cross-linking of the polymer chains occurs to form cross-linked polymers. The reaction can also be accelerated by using a catalyst. Silane crosslinked polyethylene is widely used in low-voltage cable insulation and jacketing, as well as in pipes for hot or potable water, including underfloor heating pipes. Heat resistance is the main reason for the use of cross-linked polymers in cables and pipes; not only this, but cross-linking also improves the following properties: tensile and breaking strength, chemical resistance, scratch resistance, and memory effect. LT-171 also serves as a copolymerising monomer for the synthesis of various polymers such as polyethylene and polyacrylic acid. The polymers so synthesised have improved adhesion to inorganic surfaces and can also be crosslinked in the presence of water vapour as described above.

Adhesion promotion and surface modification

Because of its ability to react with inorganic fillers as well as with organic polymers (activated by e.g. peroxides or radiation), LT-171 acts as an efficient adhesion promoter for various mineral-filled polymers, improving mechanical and electrical properties especially after exposure to moisture. Once bonded to inorganic filler, LT-171 hydrophobates the filler surface, improving the compatibility of fillers with polymer, leading to a better dispersibility, reduced melt viscosity and easier processing of filled plastics. The pretreatment of glass, metals, or ceramic surfaces with LT-171 improves the adhesion of coatings on these surfaces and can thus improve the corrosion resistance.

As co-monomer for polymer dispersion

Polymer dispersions (e.g. styrene acrylics), modified with LT-171 show improved adhesion strength in wet conditions and wet scrub resistance.

As moisture scavenger

The electron withdrawing effect imparted by the silanes vinyl functionality enhances the rate of hydrolysis. This increased reactivity makes LT-171 silane one of the fastest hydrolyzing alkoxy silanes available. The elevated rate of hydrolysis is sufficient to enable LT-171 silane to be utilized as a moisture scavenging agent in moisture sensitive systems.

LT-171 silane can be incorporated into urethane, silylated polyurethane (SPUR prepolymer) or other silane modified polymer based sealants and adhesives to extend the systems shelf-life.

Other applications of LT-171

LT-171 can easily bond to OH-groups. Hydroxyl containing polymers e.g. functionalized silicones, may be modified with LT-171, thereby introducing reactive vinyl groups into the polymer chains. The vinyl group of LT-171 is activated by its proximity to silicon, which makes it an attractive molecule for different organic syntheses.

鄂公网安备 42900402000406号

鄂公网安备 42900402000406号 Home

Home Tel

Tel Product

Product